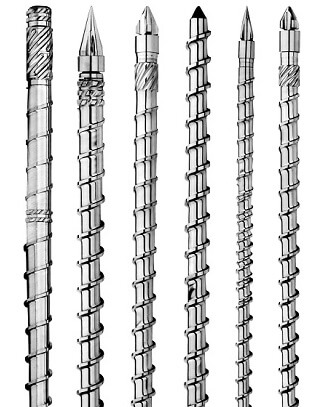

The entire plastic pipe production companies mainly aim at cost-saving. But at the end of the day, a company can only say that their product is good as the machine produces. So, it is needed to make investment in machinery that is composed of high-quality material instead of involving lots of brains. Most of the industrial owners are curious to know why is it important to have an extruder machine that is complied with a bimetallic screw barrel. The answer is quite simple. The bimetallic extruder is acknowledged to have hard protective coatings which are about 1-2mm thick. It is applied for working on the surface of the extruder pipe that is hard to work with to gain a durable and reliable experience related to production.

Do you require a tough extruder?

Off-specific plastic or produced plastic pipe which can be recycled has the potential to count on extruder machines. While purchasing a new extruder one needs to go with a bimetallic screw barrel which offers a selection range between options like recycled or spec plastic. These options are cost-effective and even offer their service without sacrificing the features and performance of the extruder machine. It is the best source that allows optimal performance, resistance against moisture to fatigue, strength along with several other controlled processes. Some factors impose extra strain on the extruder throughout the lifetime of the machine.

Which is the best material?

When it comes to material for the production of bimetallic products then the only option is recycled or off-spec raw materials. Making use of recycled materials for the production of drip irrigation or plain plastic pipes is considered an eco-friendly option. It is eco-friendly because it helps in reducing waste which helps to cut down the cost of material used. Howsoever, reground plastics have the greater possibility to contain traces of impurities, particles other additives related to plastic which could cause additional wear or even random performance while extrusion is executed. Recycled material is found to be rough, impure as well as harsh over the bimetallic extruder screw barrel which is good to provide smooth function even after prolonged use of the materials.

The multi-layer cross-head:

Screw barrel manufacturers have aimed to provide the pipe manufacturers with 3 layers cross-head concept which will reduce the cost price of the raw material used for replacing approx 80% of virgin raw material along with recycled plastic. The crosshead of the extruder covers the middle layer which comprises of recycled plastic having inner as well as an outer layer composed of 20 % virgin material. This finally leads to high-cost effective pipes to supply drinking water because the recycled core of the pipe cannot come in touch with the freshwater. This 3 layer crosshead helps the manufacturers for adding approximately up to 4 colored stripes. The use of 3 layers cross head helps in saving money without compromising the quality of the pipes.

Manufacture of the extruder with PVC:

PVC is the world’s 3rd most widely used synthetic plastic polymer that can introduce another option in the range of extruders without using bimetallic components. The raw PVC material results in increased friction that causes additional strain to the extruder which highlights the major reason behind the use of twin screw, in case of PVC extruder plastic. Above all, with the utilization of two screws, a few of the materials like PVC or recycled plastic proves to be detrimental to the health of the extruders. Therefore, it is always recommended for extruder machines to make use of the bimetallic twin screw barrel that would serve as a good friend for the PVC pipe production which is required to counteract pre-mature wearing, reduced maintenance requirement to results in the saving of the energy consumption.

The benefit of high-quality extruder:

Purchasing a durable extruder is considered to be an economical as well as a quality advantage approach. Extruder falls in the category of minimal periodic maintenances mark the checkpoint on the production of the downtimes as well as spare part costing for the terms of maintenance. But when it comes to tough extruder screw barrels, then one should know that recycled or off-spec materials can be easily handled and even save the cost of raw material. The extruder is considered as the heart of pipe production and even more than a simple piece of machinery that could easily affect the quality of the finished product.

Conclusion:

Mahira Polyglobal LLP is assumed that a quality extruder is featured with less maintenance if properly operated saves production downtime, part replacement and energy consumption. It allows making use of recycled or off-spec material without imposing any sort of side effect on the finished product or extruder. They offer a wide range of bimetallic screw barrel extruders by making use of world-class manufacturers. All of the tough extruders are known to have top-notch water-closed circuits along with unique barrel cooling systems as well as ceramic heating elements.