Screw Barrel is considered an essential part of any kind of plastic processing machinery. Without both of these, no process can reach its end-stage. With the help of screw and barrel, the process of the production would be more smooth and the industrialists are more prone to get their desired output of the production.

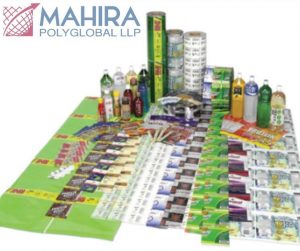

Mahira Polyglobal LLP is one of the reputed screw barrel manufacturers as well as exporter of different ranges such as injection moulding screw, SS screw & barrel, twin parallel screw barrel as well as bimetallic barrel etc.

It is one of the significant internal equipment of plastic production machinery with the help of which the whole procedure takes place in a more organised way. Both screw and barrel can be assessed with the help of modern testing equipment for delivering suitable to the customers.

Why are screw and barrel significant?

Screw Barrel plays a very crucial role in enhancing the functionality, performance of the machines. There is also the availability of advanced forms of it such as the extruder screw barrel which helps in generating greater output with minimum maintenance.

Different kinds of extruder screw barrels serve their applications in the rubber industry, pellet extruder, laminating, granulation machine as well as blown film extrusion. The manufacturing of screw barrels is done in a wide range of materials such as PP, LDPE, HDPE as well as PVC according to the specification of the clients.

What are screws and barrels subjected to?

Screws and barrels are regarded to be subjected to three different kinds of wear. The users would be able to take the right action if they are aware of which kind is present in their machinery.

#1. Abrasive wear

Damage in surface induced by glass fibres, fillers, calcium carbonate, titanium dioxide tints as well as talc falls in the category of abrasive wear. A little amount of metal is removed by granules from a screw barrel. The hard elements which are present in screw and barrel help to minimise such wearing.

#2. Adhesive Wear

Galling is one of the conditions which is produced by the interaction of one metal to another metal. Overheating takes place because of enough friction and some particular metals might weld to one another which would push away since the screw starts rotating. Such forms of wear can be avoided with appropriate alignment, clearance, toughness as well as components.

#3. Corrosive Wear

After the heating of a resin, discharge of corrosive chemicals takes place. That’s how chemical attacks upon the surfaces of screw barrels take place. One of the common occurrences is when hydrochloric acid or HCL emits as PVC degrades.

Some of the other resins feature emission of corrosive chemicals such as fibre scaling agents, ABS polycarbonate, flame retardant compounds, polysulfones as well as cellulosic.

To not experience such issues it is recommended to avoid heating. You should refrain from operating the equipment at full speed for a longer duration.

What are the characteristics of an extruder screw barrel?

The extruder is referred to as equipment that is purely made up of coupled electronics as well as mechanical units. A core of any extruder or a screw is located inside the complex of such mechanical systems.

The core is provided support by such interconnected parts. The motors as well as the gear of the extruder provides proper assistance about which tasks should be performed. Such actions are not nearly possible without the core.

The extruder won’t be able to fulfil its aim without the presence of a screw to transform rigid plastic into a flowable mass.

Some of the characters are as follows:-

The design as well as specifications aspect of an extruder screw and barrel which are the mechanism by which all the materials are carried entire extrusion are as follows:-

- The specific angle of the pitch as well as helix

- Diameter, length and L/D ratio

- Conformation geometric such as mixing sections as well as barrier flights

- Construction material and surface finish

- Ratio of compression

- Requirement of axial holes for thermoregulation

What are the different factors influencing wear?

Following are some of the factors which influence wear:-

- Straightness of screw and barrel

- The processing of the current material

- Proper alignment of the drive, screw and barrel

- Uniform heating in the barrel

- Fillers which are pigments, abrasive well as reinforcing agents

- Materials for both the barrel liner and surface of the screw

- Corrosion

- Wearing on the surface of the screw and barrel

- Incorrect support of the barrel

- Overloading the barrel at its discharge end

- Massive back pressure in entire the recovery process

- High revolutions of screw per minute

The users always look for such screw barrels which have wear resistance features, good abrasion as well as corrosion features.