A screw barrel holds utmost importance in any plastic processing industry. It fills the requirement for the processing of plastic machinery. The process of production cannot be reached to its end stage without the usage of screw barrels. With the help of a screw barrel, the production process can be carried out more conveniently. Moreover, the desired amount of output can be easily accomplished.

What are some of the features of a screw barrel?

Some of the different features of screw barrel are as follows:-

- The materials constitute lower maintaining capability along with impeccable strength as well as robust structure.

- It offers outstanding durability and it is easily available at both standard as well as customizable models.

- The products can be purchased at a very reasonable price in industries.

- If the product is subject to repair, then it can be repaired easily without any complications.

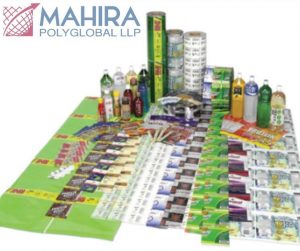

Mahira Polyglobal LLP ensures the finest quality of screw barrel and the designing of the product is done eloquently. That’s why the product is ideal to screw by both its inner as well as outer diameter. The product for the injection molding machine is available in wide ranges of diameter usually ranging from 26mm to 45mm.

Which kind of industry uses screw barrels?

Some of the applications are detailed below:-

- Small scale industries

- Food processing machinery

- Cable wire machinery

One of the primary purposes of screw barrel manufacturers is to manufacture the product in such a way that the production process is carried out without any complications. Moreover, the goal of the output is achieved.

Which material is considered best for screw barrels?

Nitriding steel is one of the best materials for screw barrels which can be hardened around 60-65 HRC. The level of hardness is significant since wear resistance is not only dependent on hardness but also on its overall strength.

This is one of the reasons why a D2 whiff possessing the same level of hardness is more resistant to wear rather than nitriding steel. A widely used hardfacing alloy commonly 56 which is branded commercially is used for protection of wear loss. It also constitutes lesser HRC hardness value in compassion to post nitriding hardness.

However, the screw which is more than 1200 mm in length is not commonly used because of its hardening process and at the same time it’s quite exorbitant when compared to nitriding steel.

When it is recommended to replace an extrusion barrel?

As barrels wear, the level of clearance between both the screw fight as well as barrel wall tends to increase usually in the higher areas of the pressure of the barrel. Purchasing a brand new screw for a worn-out barrel doesn’t nearly solve the problems related to clearance.

It might make it better for you, but it’s not an appropriate fix for your worn barrel. Since barrels are only worn in the higher areas of pressure or during the placing of fusion of the polymer which measures the endpoint of the barrel ID.

A bore gauge is widely used for measuring wear along the barrel. The screw barrel manufacturer ensures that the screw wear should be kept in mind along with the barrel wear for determination of the overall clearance. There are also different tools which are available in the market for measuring barrels.

Why lining barrels in extrusion is not popularly used?

The barrels are usually longer. In extrusion except injection molding, the screw is only capable of turning in one direction. When a few sleeves are shrunk from the heat in the barrel they are not likely to match evenly.

Grinding the inside of the diameter of the barrel might consume a lot of hours for proper functioning as well as performance which might cost you a little higher. Both the highs and lows of the barrel would be followed by it which is not likely to yield a straight bore.

The hone reduces the level of thickness of the inserted bimetallic liner.

What are some of the complications associated with it?

Some of the issues which might crop up are as follows:-

- The shrinking and spinning of the sleeves.

- The sleeves could be welded to screw flights if it becomes excessively tight due to the highs and lows of the honing barrel.

- Having lower heat transfer from the heater bands because of several metals along with the space between the ID of new sleeves as well as OD of barrel tube.

Hence, these are some of the complications. Although it’s quite simple to repair them if they get damaged. That’s a good point since they are very significant and needed during the process of production for many different purposes.