LDPE or Low-Density Polyethene is one of the widely used labels. LDPE labels are widely recognized for their fantastic flexibility, rigidness, durability as well as transparency. These are used for dry cleaning bags, sandwich bags, grocery bags, cling wrap as well as squeeze bottles.

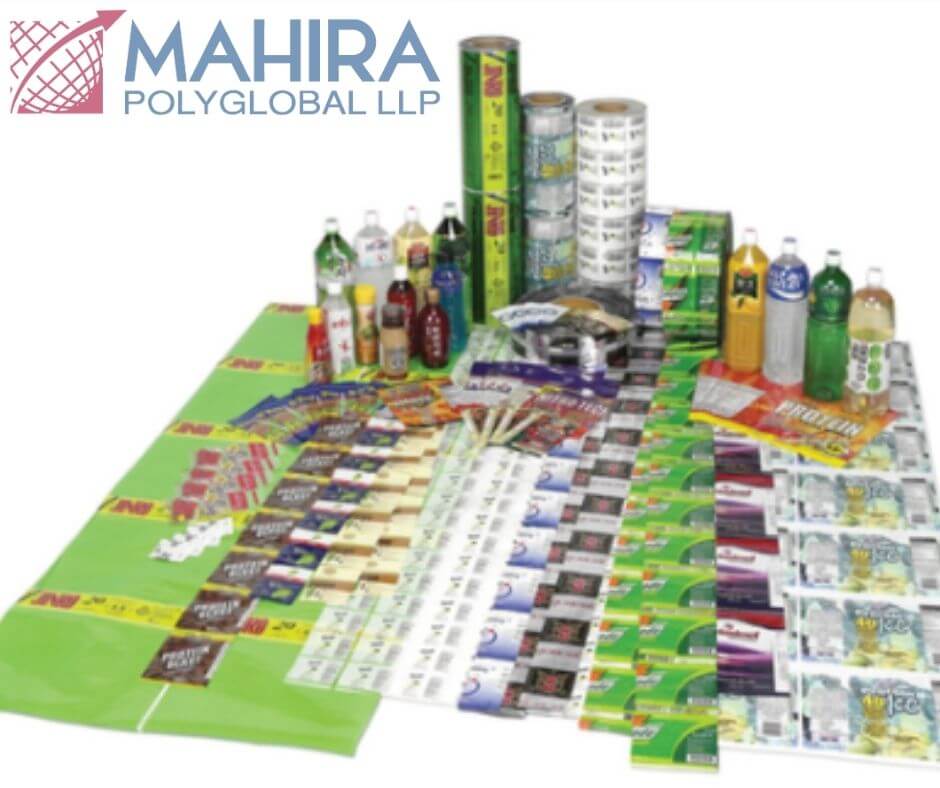

Mahira Polyglobal LLP is one of the leading LDPE labels manufacturers. The manufacturing of LDPE labels is done in a wide range of beautiful colours along with attractive designs. The printing is done in such a way that it would steal the attention of the customers.

As a result, which would help in escalating the value of the brand and would also enhance the conversion value of your product in the competitive market. Different options of shrink labels such as OPS, PET as well as PVC are available.

How efficient are LDPE labels?

The other name of LDPE labels is Printed labels or Shrink labels. The production of this label is done from a virgin as well as a topmost grade higher durable raw materials. The industries earn a lot of profit while manufacturing and selling LDPE labels.

The highlight of any brand is very essential when it comes to promoting the products and attracting a wide range of customers. This is the requirement of every brand/ product that the engagement of their product increases.

With the help of LDPE labels, the name of your brand can be boosted to a larger extent. At the time of highlighting the brand on any of the products from top to bottom or from every side then such labels would offer a 360-degree effect.

What are some of the applications of LDPE labels?

The LDPE lakes are popular for bottles as well as cans. In comparison to regular labels, the way to apply shrink sleeves includes shrinking of film sleeve with heat and immediately applying it to the product which would give the identical shape as the design of the product.

The printing of LDPE shrink labels can also be done on rotogravure machines as well as demographic digital. These are always in massive demand because of their application in multiple products, 360-degree art, 8 colour digital processes as well as 3D proofing.

The printed labels are considered to possess higher durability, be more stylish, easy to apply, safe and secure as well as create full branding in comparison to traditionally printed labels.

It is suitable for both polyester as well a plastic film but it can also be fixed easily on aluminum cans.

It is used in a wide range of applications such as electronics, food products, electric, pharm, printing, beverages, consumer products as well as automobiles. The production of LDPE labels is done in various shapes, colours designs as well as printed according to the specifications of the client.

What are the features of LDPE labels?

Some of the features of LDPE labels are as follows:-

- Easy fixation

- Scratch Proof

- Light-weighted

- Cost-effective

- Enhances the look of the product

- Highlights the value of the brand

- Highly resistant to fungus, water as well as moisture

- Attractive design along with finishing

- Electro insulation characteristics

- Resistant to oil and dust

- Incredible colour along with printability choice

It is widely popular in the wire as well as cable applications since it possesses stable electrical qualities. It is usually not recycled but it is popularly used in furniture, lumber as well as garbage cans.

Just like different other PE products, this can be used in lab bottles, mostly the ones which constitute narrow necks like droppers as well as wash bottles.

Frequently Asked Questions (FAQs):-

Q1. How much is the melting point of LDPE?

A: The polyethene molecules are prevented by the branches so that they are not packed closely in crystalline, hard as well as stiff arrangements. The melting point of LDPE labels is around 110°C or 230°F.

Q2. Why is LDPE regarded as an additional polymer?

A: Low-Density Polyethene or LDPE is considered to be one of the first commercial polyethene in which peroxide catalyst is used at a temperature ranging between 500°C to 1000°C atmospheres of pressure. This is quite lower in density and meanwhile yields a transparent polymer.