The development, as well as designing of the Waste yarn bobbin cutting machine, is done in such a way it can easily cut waste from the bobbin of the popular tape plant machine. This machine is considered to be electro-mechanical integrative. The waste yarn is being cut from the bobbin with the help of sharp as well as hot heated blades with higher efficiency.

At the time when a bobbin is passed from this machine, it’s very easy to clean them from the waste fall as well as waste yarn beside the bobbin. This also reduces the requirement of manpower by yielding higher production in comparison to manual waste yarn cutting.

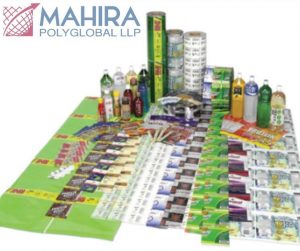

Mahira Polyglobal LLP manufactures the finest waste yarn bobbin cutting machines which save power and also reduce the loss of additional heat.

What are the features of a waste yarn bobbin cutting machine?

Some of the features are as follows:-

- It can save power up to 35% by using newer technology energy saving jackets.

- Since the machine is semi-automatic it eliminates excessive use of manpower.

- It saves ample money and time as the rate of the production of the machine is higher than the manual cutting process.

- A precise controller moderates temperature of the blades which might vary as per the requirement.

- Easy to operate and can be easily used by a layman.

- The absence of moving parts near the working space operates by assuring proper safety of the operator.

What are the different types of plastic machinery?

Some of the types are detailed below:-

#1. Vacuum Forming

This process uses a particular sheet of plastic which is further heated to a malleable temperature followed by stretching onto a single-surface mold. After this, it is forced against the mold with the help of a vacuum.

The sheet is held by the force of the vacuum until the cooling and hardening process. As a result, it retains the shape of the mold. Vacuum molding is used for the creation of different larger parts, protective covers, masks, toys as well as signs.

#2. Shredders & Granulators

This is widely used in the procedure of recycling and shredding material as well as plastics. The working of the shredders works very identical to household paper shredders which reduces the wastage of plastic to smaller as well as manageable sizes. Which makes the process of shipping and handling much easier. This is the primary requirement for off-site recycling purposes.

#3. Rotational Molding

The working of the rotational molding is quite similar to a cement mixer which holds a pre-shaped mold. The filling of the mold is done with dried cool plastics along with various other materials. This is further rotated for spreading the cool along with dry pellets around the mold.

Conclusion:-

Plastic is one commonly used material for the process of manufacturing in the world. There are different types of machines that are available in the market which can perform lots of unique as well as specialized tasks.